Does your tool performance measure up?

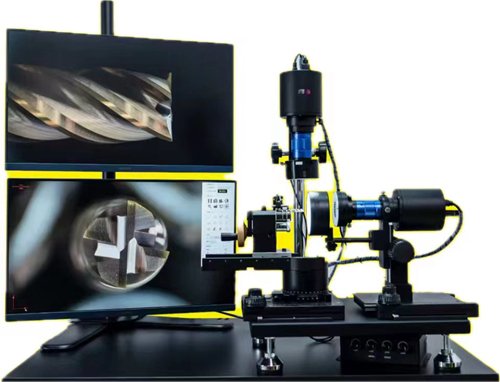

Deterioration Analysis is a brand-neutral assessment process, that can be done on site or remotely in just days, comparing your tool usage to industry norms for a clear picture of potential savings in tool and machining cost, increases in productivity, and reductions in downtime, scrap and re-work.

Traditional methods of analyzing machining process issues such as technological tool wear analysis fall short when it comes to equating the effect that tool life plays on overall shop performance. The result is that you may be underestimating and, in many cases, missing the true impact of interrelated issues such as machine utilization, quality, delivery and of course tool cost.

Benefits of a tool wear analysis

Global Tool Deterioration Analysis helps you understand key issues that impact your whole operation, such as:

- Cost of Goods Sold

- Machine set-up or change-over efficiency

- Tool Flow Management

- Overall Equipment Effectiveness

- Cutting tool and cutting strategy selection procedures and routines

- Machining operator and engineer knowledge level and skill set

Key outcomes

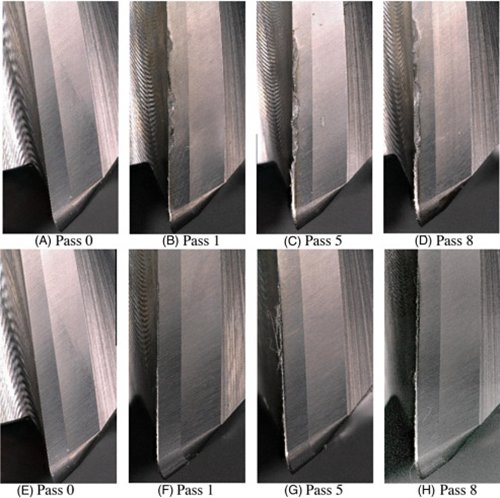

- Quantifying wear patterns

- Measuring tool wear

- Link with potential machining issues

- Evaluate potential savings

- Issues addressed

- Tooling and machining cost

- Machining process stability

- Quality of finished workpiece

- Knowledge and skills of machining operators and engineers

We always focus on increased efficiency and productivity – for your competitive advantages.