Industry

Every industry makes specific demands on its manufacturing processes. BOHLENTE’s machining (in the sense of chip removal) technology offers solutions that are tailored perfectly to customer and current market requirements. We trust in the high quality of our products and in the certainty that we can offer great customer benefits achieved through industry-specific research and development work.

-

Machining

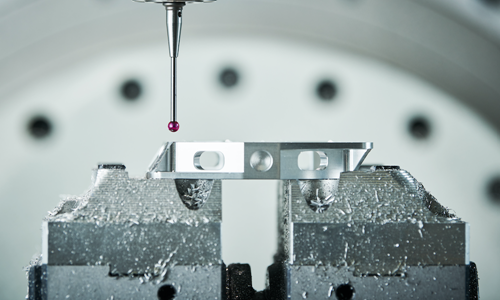

Chip-removal processes such as milling offer a high degree of accuracy and create a wide range of machining options.

-

Medical Technology

Precision and reliability are key to the manufacture of medical equipment – and in the end, this is vital when it comes to saving lives.

-

Toolmaking

With a production share of up to 50% and more, milling is one of the core technologies deployed in tool and mold making. A study has revealed that the technological possibilities are at present not being fully exploited.

-

Precision Engineering

Originating in the manufacture of mechanical watches, precision engineering still requires high-precision manufacturing processes that produce extremely accurate results.

-

Aviation Industry

Machining in the aviation industry means high-tech solutions and innovation. New materials must be able to be processed not only cost-effectively but also with great process reliability and precision.

-

Watch Industry

The fabrication of high-quality watches requires precision work and flawless surface qualities. With its Bohlente technology, Bohlente offers a perfect solution for high-precision micro-milling in finishing and superfinishing.

Maching

Increased fuel efficiency requires the use of new and challenging materials to accommodate higher fuel-burn temperatures in the hot section of jet engines. In the cold section, weight is the main driver.

Customers expect cost reductions and concessions from suppliers while at the same time production automation for complex parts increases the need for streamlined manufacturing processes.

Throw into the mix the fact that as experienced workers retire and young talent turns away from the manufacturing industry, the resulting skills gap complicates hiring and further increases the need for automated, unattended production.

Luckily, we provides the holistic combination of programming, tool paths, machining strategies and tools drawing on years of industry experience, expertise, and constant research into process improvements.

Medical Technology

The medical industry has experienced substantial growth in recent years, a trend expected to continue due to a variety of factors. Increasing life spans across the world have led to a greater demand for implants, while health issues such as obesity, arthritis, disease and trauma have put more strain on many individuals’ health.

The worldwide economic issues of the past several years have created a growing demand to reduce costs, leading to substantial research and development into new materials and processes. Additionally, higher levels of regulation have created a need for more predictable and stable manufacturing methods. As these trends continue, medical manufacturers will face the ongoing challenge of adapting to an evolving market.

we has worked closely with global medical manufacturers, building a foundation of expertise that makes us a valuable partner to those serving the industry. We also partner with research institutes, universities and other industry entities to fully understand the challenges medical manufacturers face and develop the solutions to overcome them. Our own R&D focuses on the advanced technologies, tools, strategies and component solutions that will drive and evolve your processes.

Toolmaking

With a production share of up to 50% and more, milling is one of the core technologies deployed in tool and mold making. A study has revealed that the technological possibilities are at present not being fully exploited.( The use of high-performance tools from BOHLENTE holds considerable potential and helps to reduce setup and machining times and to optimize process sequences.)

Precision Engineering

Originating in the manufacture of mechanical watches, precision engineering still requires high-precision manufacturing processes that produce extremely accurate results. (Individual machining procedures depend on the use of high-precision tools. Bohlente’s tools offers our customers tool solutions for the cost-effective production of complex geometric components.)

Aviation Industry

Machining in the aviation industry means high-tech solutions and innovation. New materials must be able to be processed not only cost-effectively but also with great process reliability and precision. (BOHLENTE is constantly engaged in research and development work and is as a result an experienced and skilled partner when it comes to developing customer-specific solutions that meet the strict quality requirements of the industry.)

Watch Industry

The fabrication of high-quality watches requires precision work and flawless surface qualities. With its Bohlente technology, Bohlente offers a perfect solution for high-precision micro-milling in finishing and superfinishing.