The machining of hardened steels with a hardness of more than 50 HRC, e.g. for the machining of injection molds, is a demanding task:

The material is both hard and tough, and the addition of corrosion-resistant alloy components further increases the complexity of the machining task. Due to the high feeds and extremely high cutting temperatures at cutting speeds of up to 250 m/min, cutting tools face enormous challenges.

At the same time, even the smallest mold contours require the highest surface quality. All this places extremely special demands on precision tools.

Product Features

- Sharp cutting edge, excellent balance between cutting life and surface finish.

- Medium machining and finishing can maintain high efficiency.

- Chipping-resistant material matrix and excellent toughness of the coating can meet the different processing.

- Suitable for the processing of HRc18~45 steel materials, such as: P5/P20/NAK80/SUS304, etc.

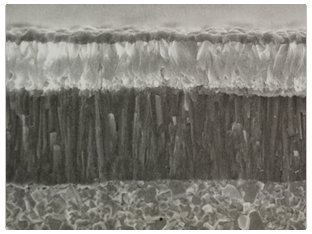

- A newly developed coating material containing silicon has been specially developed for the machining of hardened steels with a hardness of more than 50 HRC.

- Thanks to its outstanding properties, it is the ideal solution for hard machining, whether dry or wet, milling, drilling, reaming or threading.

- This coating material is characterized, on the one hand, by its high hardness and, on the other hand, by its toughness and excellent adhesion, in addition to its high wear resistance.

- In addition to the dense layer structure, the addition of silicon ensures high thermal stability of the tool.

Square

Ball

Radius Nose

Long Neck