Product Features

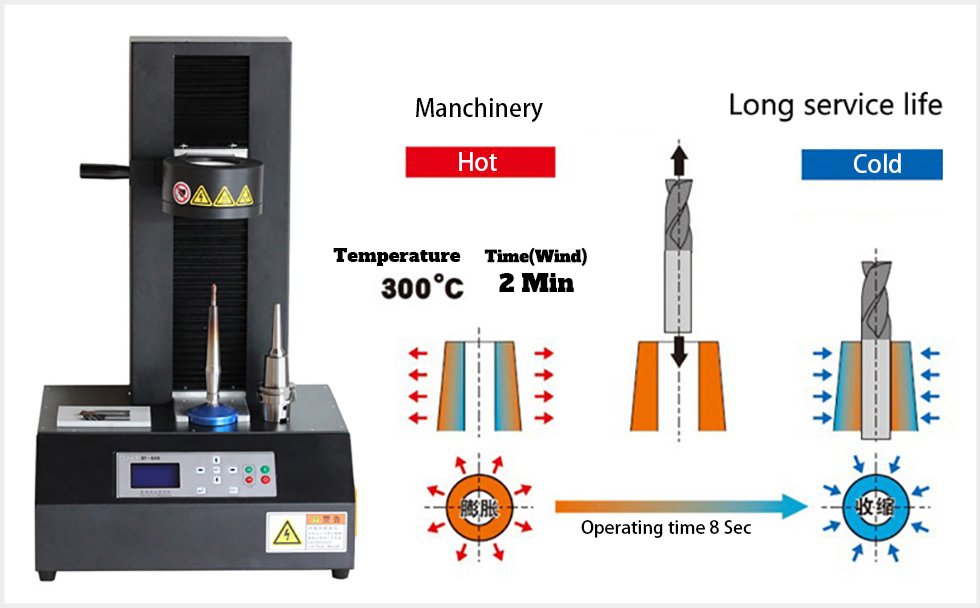

1.fast loading and unloading of tools, the use of heat shrinkage machine heating, 13KW high power can be completed within 5 seconds of the tool installation and clamping, cooling only 30 seconds, the unique water cooling device can prevent deterioration of the accuracy of the tool shank.

2.High precision and small runout. The tool mounting part has no parts such as nut and collet required for collet chuck, which is simple and effective, the cold shrinkage clamping force is stable, the tool deflection is ≤3μ, which reduces the wear of tool and ensures the high precision in high speed machining.

3. Shank is thin and widely used. Ultra-thin apex part and rich shank shape changes can be widely used in high-speed high precision machining, deep hole machining.

4.Simple and efficient, long life. Hot loading and unloading operation, even if the same shank is loaded and unloaded more than 2,000 times, there will be no change in accuracy, stable and reliable performance, and long service life.

BT

CAT

SK

HSK